xilanh điện EAC Series

0 VNĐ

Characteristic

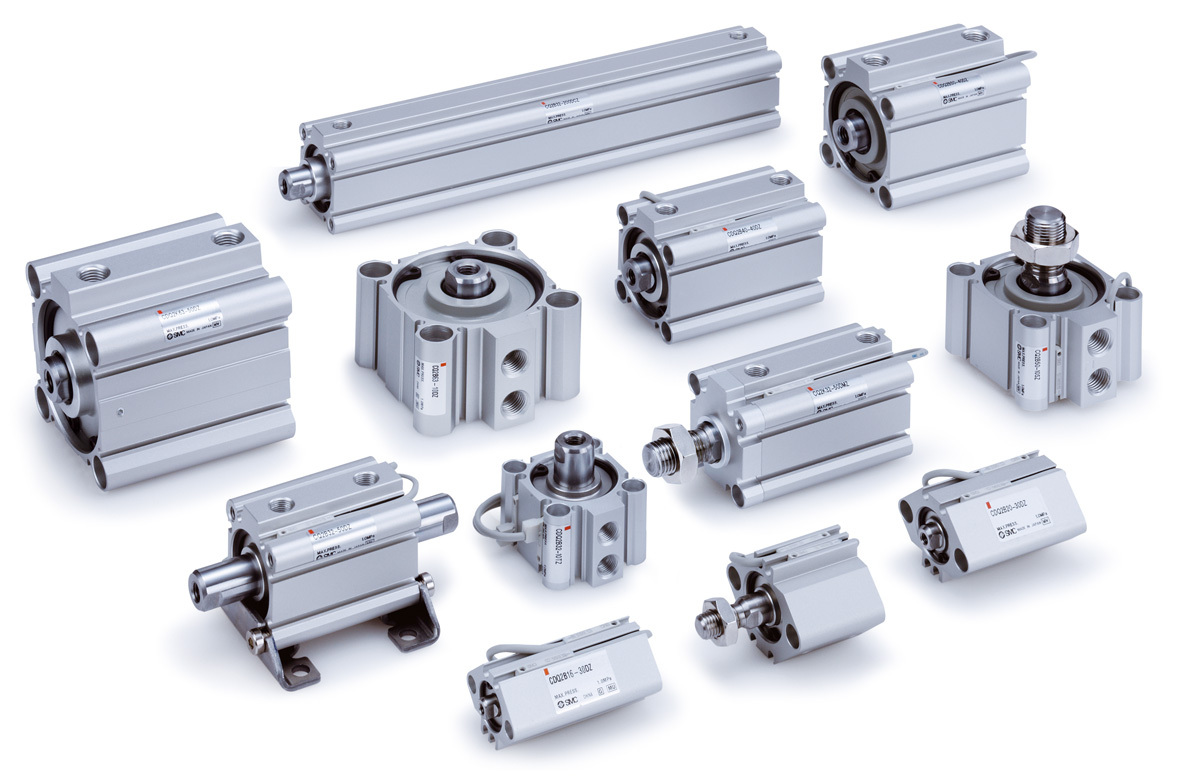

Various lineup

Motor mounting direction

Cylinder shape

Depending on the installation space, straight type and folding type can be selected, which increases the degree of freedom of installation.

We also offer a shaft guide with a guide that contributes to reducing the labor of designing and arranging the external guide of the customer, with a shaft guide cover that improves the safety of the equipment and prevents grease scattering.

Straight type, folded type are the same price. Unit price: 58,200 yen ~.

|

On-board motor

|

Stepping motor unit α STEP

AR series / AZ series |

|---|---|

|

Motor mounting direction

|

Straight type / folded type (turn right / return left)

|

|

Cylinder shape

|

Standard / With shaft guide / With shaft guide cover

|

|

Additional function

|

With or without electromagnetic brake

|

|

Type of control method

|

|

|

Type of power supply voltage

|

AC power input / DC power input

|

Variation · Specification

AR series mounted

Built-in positioning function type

|

type

|

Mounting angle dimension

[mm] |

Model number

|

Maximum payload

[kg] |

Thrust

[N] |

Stroke

[mm] |

Power supply input

[V] |

Electromagnetic brake

|

|

|---|---|---|---|---|---|---|---|---|

|

Present

|

None

|

|||||||

|

Straight type

standard |

28 × 28

|

Horizontal 15 / Vertical 5

|

~ 50

|

50 to 150

(50 mm increments) |

DC 24

|

○

|

○

|

|

|

42 × 42

|

Horizontal 30 / Vertical 14

|

~ 140

|

50 to 300

(50 mm increments) |

Single phase 100 - 120

single phase 200 - 240 DC 24/48 |

○

|

○

|

||

|

60 × 60

|

Horizontal 60 / Vertical 30

|

~ 400

|

○

|

○

|

||||

|

Straight type

shaft guide cover included |

28 × 86

|

Horizontal 15 / Vertical 4.5

|

~ 50

|

50 to 150

(50 mm increments) |

DC 24

|

○

|

○

|

|

|

Straight type With

shaft guide With shaft guide cover |

42 × 114

|

Horizontal 30 / Vertical 13

|

~ 140

|

50 to 300

(50 mm increments) |

Single phase 100 - 120

single phase 200 - 240 DC 24/48 |

○

|

○

|

|

|

60 × 156

|

Horizontal 60 / Vertical 28

|

~ 400

|

○

|

○

|

||||

|

Fold type

standard |

42 × 42

|

Horizontal 30 / Vertical 12.5

|

~ 125

|

50 to 300

(50 mm increments) |

○

|

○

|

||

|

60 × 60

|

Horizontal 60 / Vertical 30

|

~ 360

|

○

|

○

|

||||

|

Shaft type withshaft guide with shaft guide cover |

42 × 114

|

Horizontal 30 / Vertical 11.5

|

~ 125

|

50 to 300

(50 mm increments) |

○

|

○

|

||

|

60 × 156

|

Horizontal 60 / Vertical 28

|

~ 360

|

○

|

○

|

||||

Pulse train input type

|

type

|

Mounting angle dimension

[mm] |

Model number

|

Maximum payload

[kg] |

Thrust

[N] |

Stroke

[mm] |

Power supply input

[V] |

Electromagnetic brake

|

|

|---|---|---|---|---|---|---|---|---|

|

Present

|

None

|

|||||||

|

Straight type

standard |

28 × 28

|

Horizontal 15 / Vertical 5

|

~ 50

|

50 to 150

(50 mm increments) |

DC 24

|

○

|

○

|

|

|

42 × 42

|

Horizontal 30 / Vertical 14

|

~ 140

|

50 to 300

(50 mm increments) |

Single phase100 - 115

Single phase 200 - 230 Three - phase 200 - 230 DC 24/48 |

○

|

○

|

||

|

60 × 60

|

Horizontal 60 / Vertical 30

|

~ 400

|

○

|

○

|

||||

|

Straight type

shaft guide cover included |

28 × 86

|

Horizontal 15 / Vertical 4.5

|

~ 50

|

50 to 150

(50 mm increments) |

DC 24

|

○

|

○

|

|

|

Straight type With

shaft guide With shaft guide cover |

42 × 114

|

Horizontal 30 / Vertical 13

|

~ 140

|

50 to 300

(50 mm increments) |

Single phase100 - 115

Single phase 200 - 230 Three - phase 200 - 230 DC 24/48 |

○

|

○

|

|

|

60 × 156

|

Horizontal 60 / Vertical 28

|

~ 400

|

○

|

○

|

||||

|

Fold type

standard |

42 × 42

|

Horizontal 30 / Vertical 12.5

|

~ 125

|

50 to 300

(50 mm increments) |

○

|

○

|

||

|

60 × 60

|

Horizontal 60 / Vertical 30

|

~ 360

|

○

|

○

|

||||

|

Shaft type withshaft guide with shaft guide cover |

42 × 114

|

Horizontal 30 / Vertical 11.5

|

~ 125

|

50 to 300

(50 mm increments) |

○

|

○

|

||

|

60 × 156

|

Horizontal 60 / Vertical 28

|

~ 360

|

○

|

○

|

||||

Equipped with AZ series

Built-in positioning function type

|

type

|

Mounting angle dimension

[mm] |

Model number

|

Maximum payload

[kg] |

Thrust

[N] |

Stroke

[mm] |

Power supply input

[V] |

Electromagnetic brake

|

|

|---|---|---|---|---|---|---|---|---|

|

Present

|

None

|

|||||||

|

Straight type

standard |

28 × 28

|

Horizontal 15 / Vertical 5

|

~ 50

|

50 to 150

(50 mm increments) |

DC 24

|

-

|

○

|

|

|

42 × 42

|

Horizontal 30 / Vertical 14

|

~ 140

|

50 to 300

(50 mm increments) |

Single phase 100 - 120

Single phase 200 - 240 Three phase 200 - 240 DC 24/48 |

○

|

○

|

||

|

60 × 60

|

Horizontal 60 / Vertical 30

|

~ 400

|

○

|

○

|

||||

|

Straight type

shaft guide cover included |

28 × 86

|

Horizontal 15 / Vertical 4.5

|

~ 50

|

50 to 150

(50 mm increments) |

DC 24

|

-

|

○

|

|

|

Straight type With

shaft guide With shaft guide cover |

42 × 114

|

Horizontal 30 / Vertical 13

|

~ 140

|

50 to 300

(50 mm increments) |

Single phase 100 - 120

Single phase 200 - 240 Three phase 200 - 240 DC 24/48 |

○

|

○

|

|

|

60 × 156

|

Horizontal 60 / Vertical 28

|

~ 400

|

○

|

○

|

||||

|

Fold type

standard |

42 × 42

|

Horizontal 30 / Vertical 12.5

|

~ 125

|

50 to 300

(50 mm increments) |

○

|

○

|

||

|

60 × 60

|

Horizontal 60 / Vertical 30

|

~ 360

|

○

|

○

|

||||

|

Shaft type withshaft guide with shaft guide cover |

42 × 114

|

Horizontal 30 / Vertical 11.5

|

~ 125

|

50 to 300

(50 mm increments) |

○

|

○

|

||

|

60 × 156

|

Horizontal 60 / Vertical 28

|

~ 360

|

○

|

○

|

||||

Pulse train input type

|

type

|

Mounting angle dimension

[mm] |

Model number

|

Maximum payload

[kg] |

Thrust

[N] |

Stroke

[mm] |

Power supply input

[V] |

Electromagnetic brake

|

|

|---|---|---|---|---|---|---|---|---|

|

Present

|

None

|

|||||||

|

Straight type

standard |

28 × 28

|

Horizontal 15 / Vertical 5

|

~ 50

|

50 to 150

(50 mm increments) |

DC 24

|

-

|

○

|

|

|

42 × 42

|

Horizontal 30 / Vertical 14

|

~ 140

|

50 to 300

(50 mm increments) |

Single phase 100 - 120

Single phase 200 - 240 Three phase 200 - 240 DC 24/48 |

○

|

○

|

||

|

60 × 60

|

Horizontal 60 / Vertical 30

|

~ 400

|

○

|

○

|

||||

|

Straight type

shaft guide cover included |

28 × 86

|

Horizontal 15 / Vertical 4.5

|

~ 50

|

50 to 150

(50 mm increments) |

DC 24

|

-

|

○

|

|

|

Straight type With

shaft guide With shaft guide cover |

42 × 114

|

Horizontal 30 / Vertical 13

|

~ 140

|

50 to 300

(50 mm increments) |

Single phase 100 - 120

Single phase 200 - 240 Three phase 200 - 240 DC 24/48 |

○

|

○

|

|

|

60 × 156

|

Horizontal 60 / Vertical 28

|

~ 400

|

○

|

○

|

||||

|

Fold type

standard |

42 × 42

|

Horizontal 30 / Vertical 12.5

|

~ 125

|

50 to 300

(50 mm increments) |

○

|

○

|

||

|

60 × 60

|

Horizontal 60 / Vertical 30

|

~ 360

|

○

|

○

|

||||

|

Shaft type withshaft guide with shaft guide cover |

42 × 114

|

Horizontal 30 / Vertical 11.5

|

~ 125

|

50 to 300

(50 mm increments) |

○

|

○

|

||

|

60 × 156

|

Horizontal 60 / Vertical 28

|

~ 360

|

○

|

○

|

||||

Bình luận

.png)